ABOUT WORKSWELL

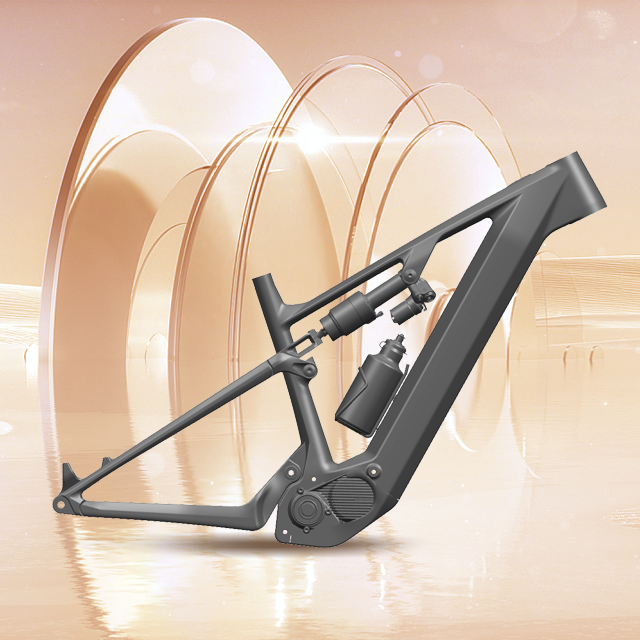

WORKSWELL BIKES

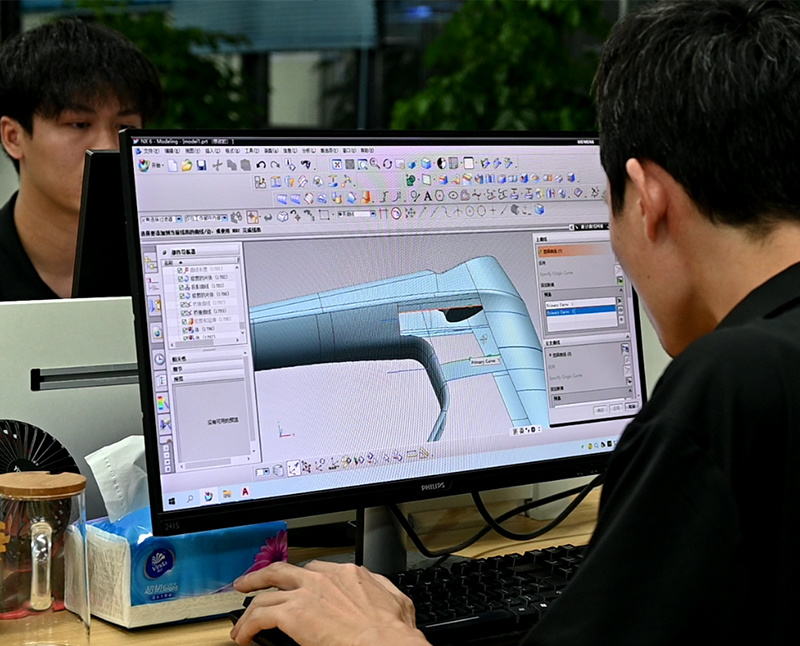

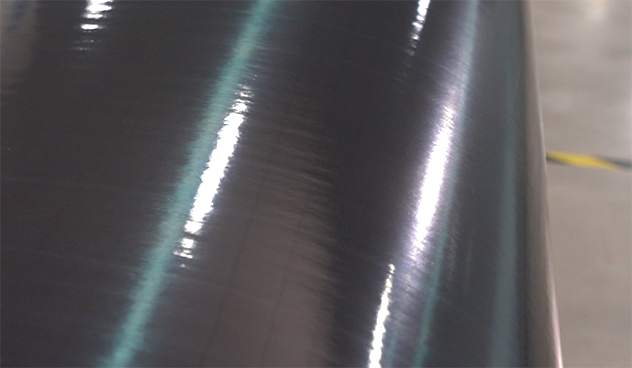

Workswell Bikes is a professional OEM and ODM manufacturer specializing in the design, R&D, and production of carbon fiber products. The enterprise has passed ISO9001:2015 certification, with a floor area of 30000 square meters and approximately 200 staff.

-

30000

㎡Factory building area

-

30

+Production management experience

-

20

+Design and development experience

-

80

%Digital chemical factory

-

PASS

ISO9001:2015

DIVISIONS

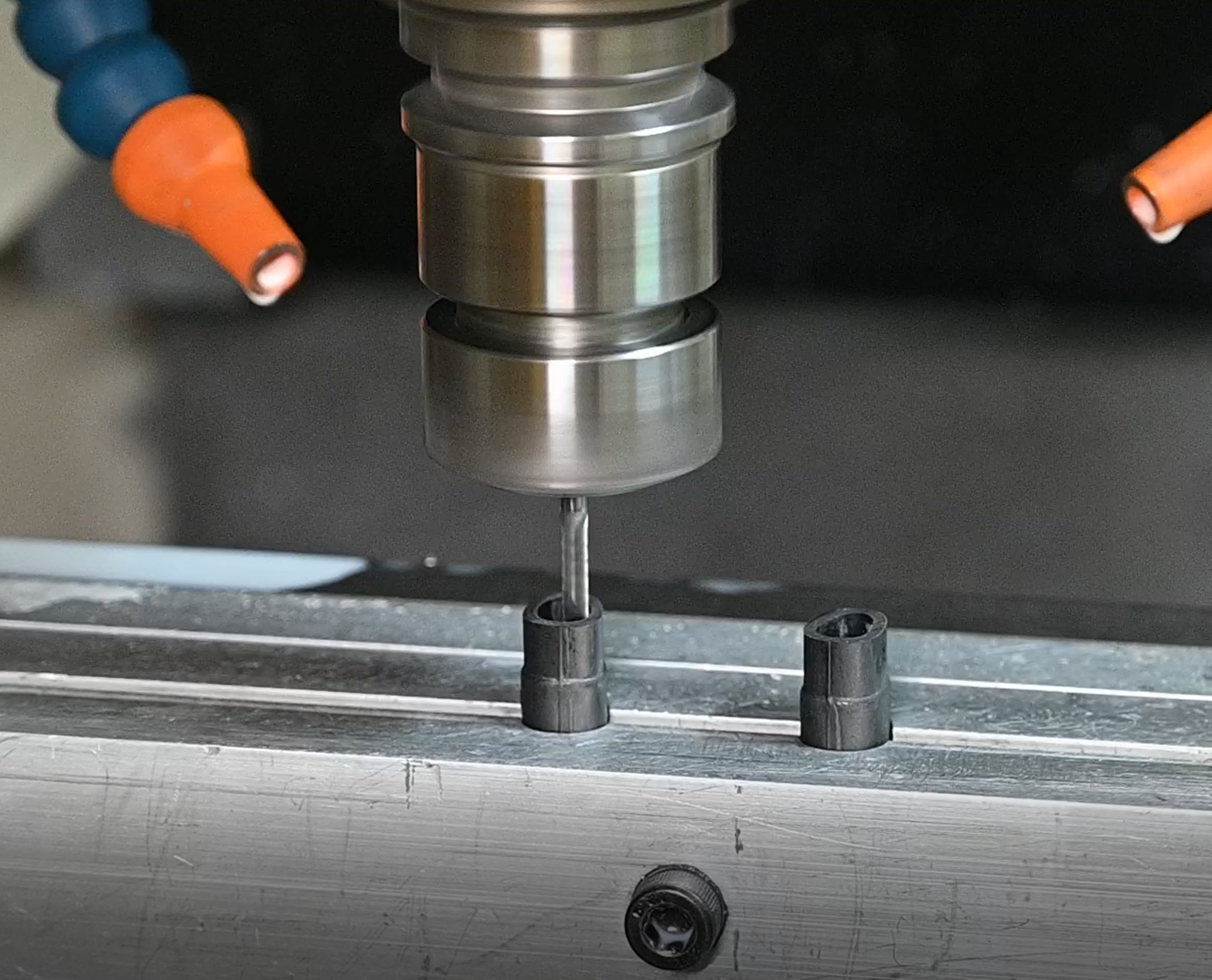

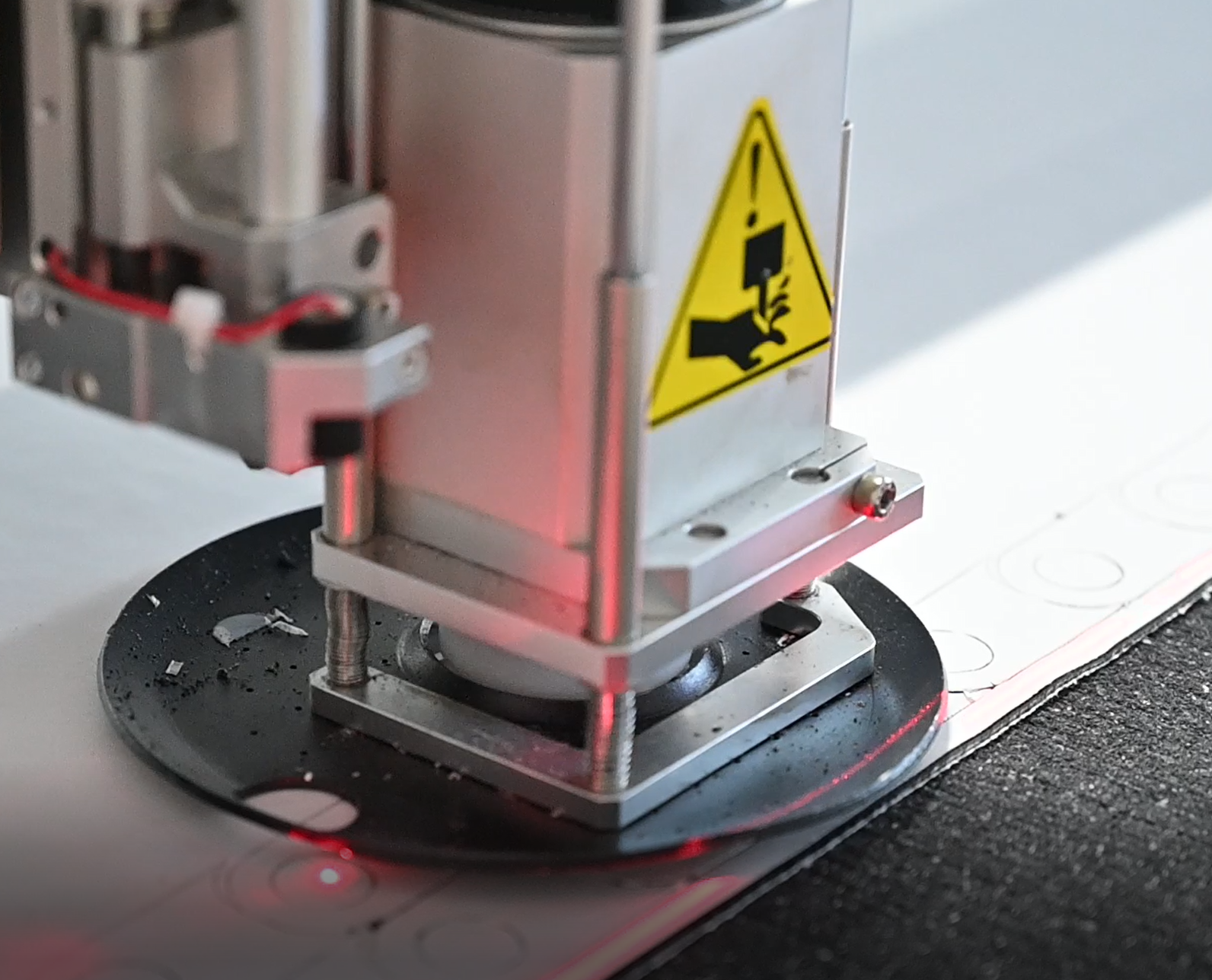

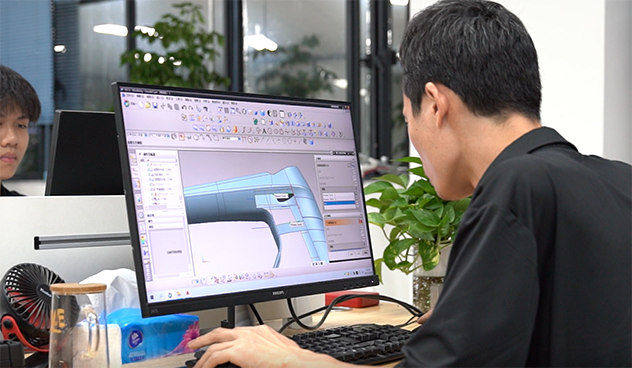

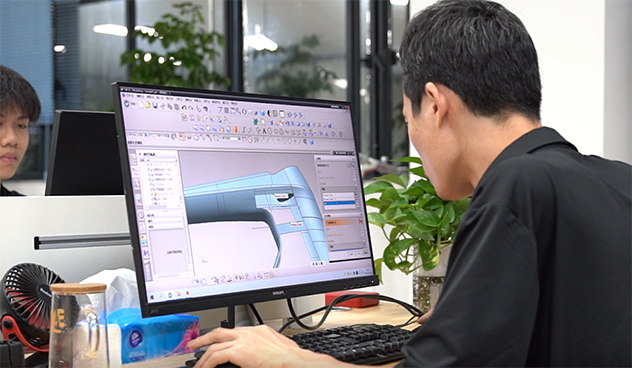

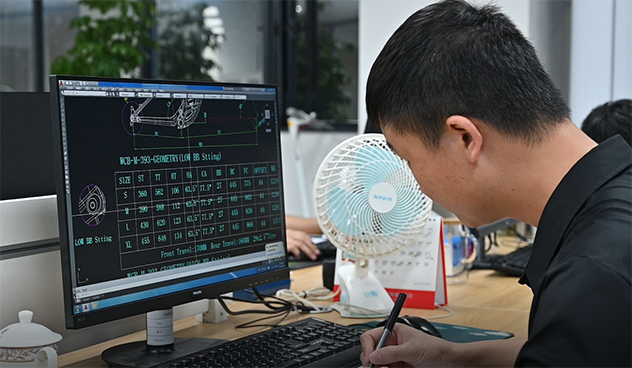

TECHNOLOGY

PRODUCTION ADVANTAGES

SERVICE PROCESS

NEWS & EVENTS

LEAVE A MESSAGE

Building A, Xiangwei Science and Technology Park, Chenjiang Dongsheng South Road, Huicheng District, Huizhou City, Guangdong Province